+

Where

endurance and

energy density

drives enablement.

-

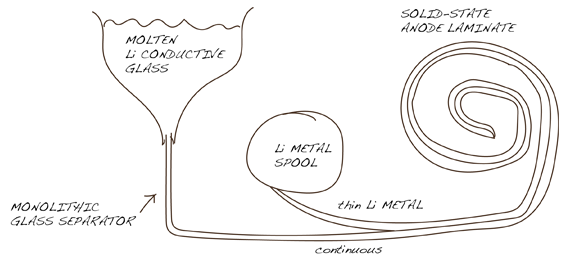

Glass-Protected Lithium Battery

PolyPlus has invented the first conductive glass separator for rechargeable Li metal batteries. Our scientists recognized that thin monolithic glass sheets have sufficient flexibility and conductance for the application and have developed a proprietary process to bond Li metal to monolithic sulfide glass electrolyte.

The monolithic glass sheet acts as a barrier to dendrites and facilitates efficient Li cycling. Continuous thin glass can be produced in volume and at competitive cost.

Twice the energy/

half the size

Glass protected lithium batteries enable lithium metal anodes to be combined with conventional lithium ion cathodes to double the energy density of lithium ion batteries or provide the same energy in a package that is half the size.

Scalable &

Manufacturable

Battery developers have long theorized that solid-state electrolytes might allow replacement of the bulky carbon electrode in Li-ion cells with Li metal. PolyPlus went a step further in developing a technology that is inherently scalable.

Low

Cost

The PolyPlus Glass Protected Li Metal Battery technology is based on abundant low cost raw materials and known high volume manufacturing. As the technology is scaled we expect costs for the solid-state Li metal anode to be competitive with Li-ion technology while offering a step-change in performance improvement.

Protected Lithium Electrode

The Protected Lithium Electrode (PLE™) is an air and water stable battery anode with a lithium metal core that enables the development of safe batteries with unprecedented energy densities and zero self-discharge. The PLE was recognized by TIME magazine as one of the 50 Best Inventions of 2011, and by the Edison Committee with a Gold Edison Award in 2012.

The PolyPlus PLE consists of lithium metal protected by a thin, dense, ceramic membrane that conducts Li+ ions. The PLE makes possible what was thought to be impossible: to build batteries that combine lithium metal electrodes with water-based cathode chemistries.

Highest Energy

Density

The PolyPlus PLE is the world’s first air-stable lithium metal electrode, and it has enabled the design and fabrication of the most compact and energy dense batteries.

Proven

Performance

World-record performance of PolyPlus Li-Air cells has been verified by the U.S. Army CERDEC. Testing at their Aberdeen facility confirmed specific energy in excess of 800 Wh/kg for 10 Ah PolyPlus Li-Air cells.

Paradigm Shift

for Battery Design

The PolyPlus PLE concept changes the way we think about battery cell design. The membrane functions as an engineered solid electrolyte interface.

The Future: Protected Lithium Electrode

The invention of the PLE by PolyPlus enables the development of a new generation of battery chemistries. PolyPlus worked with a Tier 1 battery manufacturing engineering firm to design and build a first of its kind pilot line to produce the protected lithium electrodes used in state-of-the-art lithium-air, lithium-water, and lithium-sulfur batteries. PolyPlus is now refining the PLE to enable the manufacture of ultra-compact/ultra-light batteries that can be scaled to volumes that will satisfy the global marketplace.

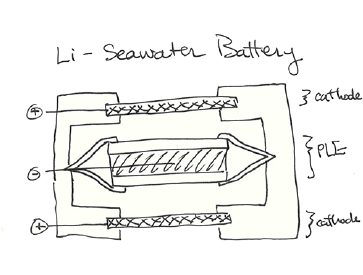

Lithium Seawater

PolyPlus developed the first seawater-activated lithium batteries by coupling the PLE with water-activated cathodes. During operation, the batteries are open to the seawater environment. The Li-water battery is safe, compact and has virtually zero self-discharge.

A battery that runs on water, PolyPlus’ Li-Seawater batteries combine the Protected Lithium Electrode (PLS) with seawater as the cathode active species. Lithium seawater batteries provide key advantages over other primary batteries (such as lithium thionyl chloride) including a 10X increase in energy density along with inherent safety. This revolutionary technology has zero self-discharge and exceptional energy density. Depending on size and form factor, the batteries can reach energy densities of 2000 Wh/kg and >1500 Wh/l, which is an order of magnitude greater than competing technologies, including Li-ion. PolyPlus’ Li/SWB represents a game changing technology for long endurance underwater/subsea applications.

Ultra-lightweight, Compact, Underwater Energy Source

PolyPlus’ Li-Seawater batteries can pack a large amount of energy into a small amount of space, and are close to neutral buoyancy.

Long Lifetime

The combination of exceptional energy density and zero self discharge, makes PolyPlus Li-Seawater batteries ideal for long duration underwater applications.

Pressure

Tolerant

For deep ocean use, the Li-Seawater batteries do not need to be housed in bulky, expensive, protective pressure vessels. PLEs have been pressure tested at 10,000 psi in hydraulic fluid and 2500 psi in salt water with no adverse effect on subsequent electrochemical performance.

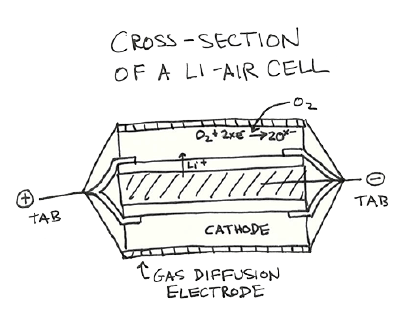

Lithium Air

To build the world’s lightest primary battery, PolyPlus couples the lithium metal in the PLE with a gas diffusion electrode, aqueous electrolyte, and ambient air. The Li-Air battery is ideal for weight-sensitive, portable power applications.

A battery that runs on air. The PolyPlus Li-Air battery is constructed by sandwiching the PLE between two cathodes in compartments specially engineered to admit air, electrochemically reduce the oxygen, and store the reaction products.

Ultra-lightweight, portable energy

The cell-level energy density of PolyPlus’ Li-Air batteries is > 800 Wh/kg. Pack level batteries deliver >500 Wh/kg.

Safety

Since the cathode for the PolyPlus Li-Air battery is water-based and uses air from the surrounding environment, the battery contains no toxic chemicals (SOCl2, SO2, CFx).

Long

Shelf Life

The solid-state PLE membrane prevents parasitic side reactions; therefore the PolyPlus Li-Air batteries have a low self-discharge rate and a projected shelf life of >10 years.

The Future: Lithium Air

Lithium-air batteries are most attractive for those applications that are particularly weight sensitive, including but not limited to soldier power and remote sensors. PolyPlus has demonstrated world record levels of specific energy (800 Wh/kg) for its existing 10 Ah Li-Air cells, and is now working to boost the power density.

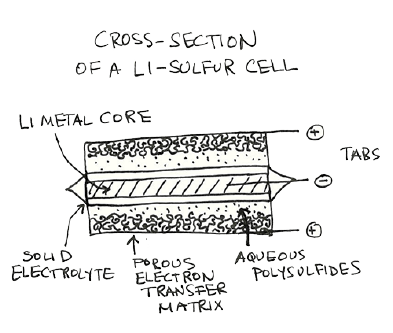

Lithium Sulfur

PolyPlus is a world leader in Li-S battery technology. Nearly all Li-S batteries, whether sold commercially or in development, use the proprietary non-aqueous electrolyte developed and patented by PolyPlus in the 1990’s. PolyPlus also developed inexpensive water-based Li-S chemistry, greatly improving the capacity and cycle life of sulfur electrodes in the process.

Compared to today’s Li-ion batteries, PolyPlus’ Li-S battery will pack the same amount of energy into the same amount of space, but at half the weight. PolyPlus’ aqueous Li-S battery pairs the PLE as the negative electrode with a water-based solution of sulfur as the positive electrode. Sulfur has almost ten times the capacity of positive electrode materials used in Li-ion batteries, and is orders of magnitude less expensive. The conventional approach to rechargeable Li-S batteries is based on the use of non-aqueous electrolytes and unprotected lithium metal foil, leading to lightweight batteries with a high rate of self-discharge, questionable safety, and poor cycle life. In contrast, PolyPlus builds its cell with protected lithium and aqueous electrolytes, leading to rechargeable Li-S cells with excellent cycle life, safe operation, and no evidence of self-discharge.

Lightweight

Rechargeable Batteries

The projected performance of rechargeable Li-S cells is over 400 Wh/kg and 600 Wh/l. With a specific energy that is twice that of competing Li-ion technology, Li-S batteries will be attractive for weight sensitive applications.

Long

Cycle Life

Using the protected lithium electrode in the Li-S cell solves the commonly observed cycle life problem. PolyPlus’ Li-S cells cycle hundreds of times without significant capacity loss.

Reduced

Materials Costs

Sulfur is one of the most abundant elements on earth, and is priced accordingly. Although Li-ion battery prices have dropped significantly over the past several years, they still present a cost hurdle for widespread adoption of electric vehicles.

The Future: Lithium Sulfur

Rechargeable Li-S batteries are still in development at PolyPlus. Initial commercialization will be focused on high margin applications where weight is a premium. PolyPlus will likely work with a partner and/or license the technology for high volume, cost-sensitive markets.